Check Valve Manufacturer

Valvesonly is one of the greatest Check Valve Manufacturer . A check valve is a type of valve that allows fluid to flow in one direction while automatically preventing the reverse flow. Check valves are designed to automatically prevent reverse flow without any manual intervention, making them a useful component in a variety of fluid control systems. It is a type of valve that prevents fluid from flowing in the reverse direction. It opens automatically when fluid flows in the forward direction, and closes automatically when fluid flow stops or reverses. They can be made from a variety of materials, including steel, stainless steel, cast iron, bronze, and plastic. The choice of material will depend on the specific application and the chemical and physical properties of the fluid being controlled. The aim of a check valve is to prevent reverse flow, minimize pressure drop, and ensure efficient fluid flow in a variety of fluid control applications. Check valves are designed to operate automatically, providing reliable and efficient control over fluid flow in a range of settings.

In a check valve, fluid flows through the valve body and into the check valve disc, which is attached to a stem. The disc opens automatically when fluid flows in the forward direction, allowing the fluid to flow through the valve. When fluid flow stops or reverses, the disc closes, preventing reverse flow.

Valvesonly is well known Check Valve Manufacturer . It is famous for its premium quality products which comes in various design and materials. All the products are tested according to requirements and standards.

Types of check valves:

• Swing check valve

• Wafer check valve

• Ball check valve

• Lift check valve

• Dual plate check valve

• Silent check valve

• Non-slam swing check valve

• Tilting disc check valve

• Pressure seal check valve

• Disk Check Valve

• Piston Check Valve

• Duo check valve

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), Duplex and Super duplex STEEL [ F51, F53, F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends-threaded, socket weld, butt weld, flanged, lug, wafer

https://valvesonly.com/product....-category/check-valv

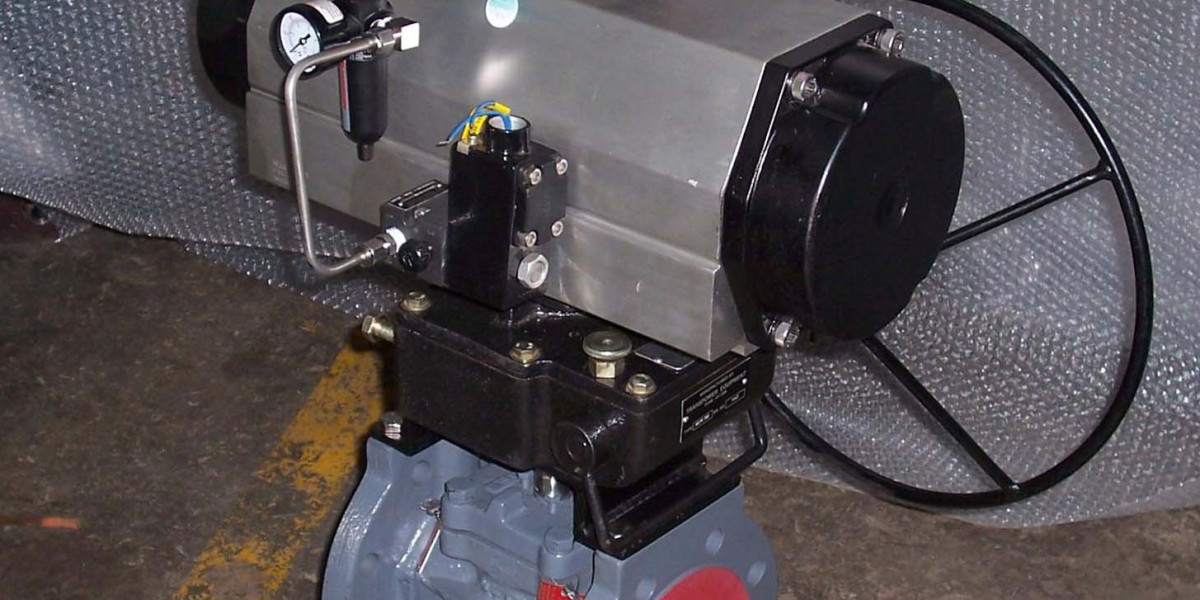

Pressure Reducing Valve Manufacturer

Valvesonly is the top Pressure Reducing Valve Manufacturer . Pressure reducing valve (PRV), also known as a pressure regulator, is a type of valve that automatically reduces the pressure of a fluid or gas to a set level. It is used to protect downstream equipment from damage due to excessive pressure.These valves are essential components in many fluid and gas handling systems. They ensure that the pressure of the system remains within safe and efficient limits, protecting equipment and personnel from potential hazards. The type of pressure reducing valve selected depends on the specific application and the required pressure range.

Valvesonly is the prime Pressure Reducing Valve Manufacturer and provides premium quality valves at cost-effective prices.

Parts of Pressure Reducing Valve:

Body

Diaphragm

Spring

Seat

Valve Disc

Inlet and Outlet Ports

Pressure Gauge Port

Adjustment Screw

Bonnet

Types of Pressure Reducing Valve:

• Direct acting PRV

• Pilot operated PRV

• External control PRV

• Balanced bellows PRV

Industries

Oil and gas

Chemical industry

Power Generation industry

Mining industry

Pulp and paper industry

Applications of Pressure Reducing Valve:

• Water supply systems

• Gas distribution systems

• Steam systems

• Chemical processing plants

• Pneumatic systems

• Fire protection systems

Advantages of Pressure Reducing Valve:

• Protects downstream equipment from damage due to excessive pressure

• Improves system efficiency by reducing energy waste

• Prevents leaks and burst pipes caused by high pressure

• Provides consistent and reliable pressure control

• Can be easily adjusted to meet changing system demands

• Low maintenance requirements and long service life.

Description-

Materials: Cast Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9) , Ductile Iron, Stainless Steel [ SS316 , SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3,F55, F91 ]

Class: 150 – 800, PN10 TO PN100.

Size: 1/2” – 24”

Ends: Butt welded, Socket welded, Threaded, Flanged

https://valvesonly.com/product....-category/pressure-r