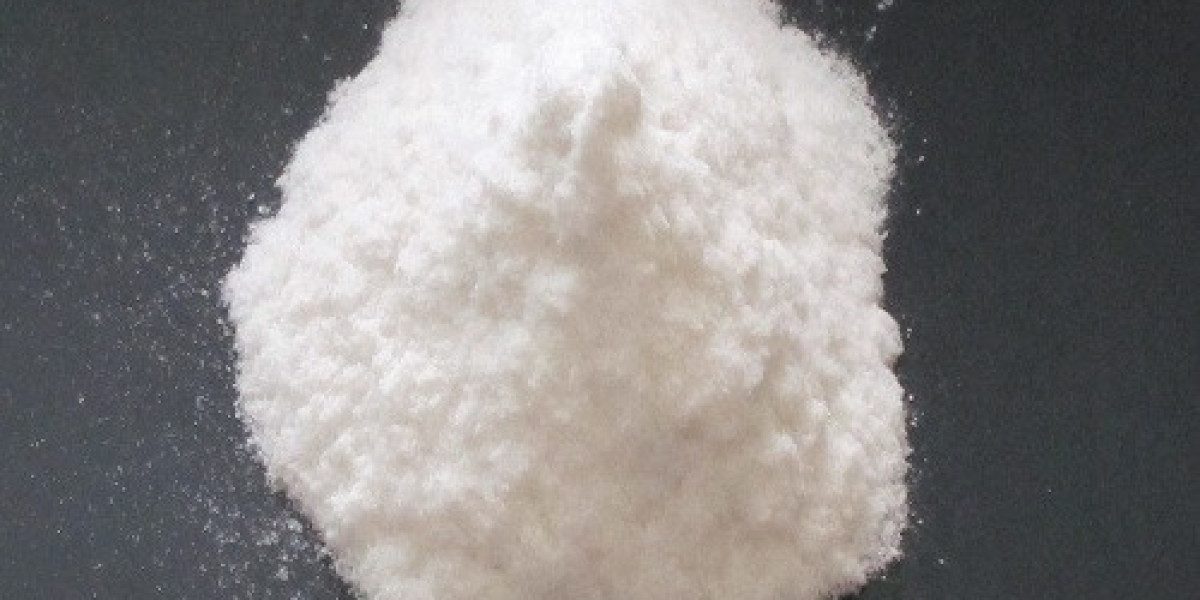

The India carboxymethyl cellulose (CMC) has been witnessing strong growth over the past few years on account of emerging new application areas. CMC finds uses across various industries such as food & beverages, pharmaceuticals, personal care, paints & adhesives, and oil & gas. The versatile functional properties of CMC including thickening, binding, suspending, film formation, and water retention have propelled its demand from these end-use sectors. Additionally, the product's properties of being non-toxic and biodegradable have further increased its popularity.

The food & beverages accounts for a predominant share of over 30% in the India CMC owing to widespread applications of CMC as a thickener and stabilizer in products such as baked goods, desserts, confectionery, dairy, meat, beverages, and soups & sauces. Properties like good solubility in both hot and cold water systems, viscosity stability over wide temperature ranges and tolerance to other ingredients make CMC highly suitable for food applications. Growth in the packaged food in India has majorly driven the consumption of CMC.

India Carboxymethyl Cellulose (CMC) : Demand From Pharmaceutical

The pharmaceutical in India has emerged as a fast-growing end-use segment for CMC in recent years. Carboxymethyl Cellulose (CMC) finds numerous applications in the manufacture of tablets, suspensions, emulsions, gels, ointments, creams and other pharmaceutical formulations. Key benefits of using CMC in pharmaceutical products include enhanced bioavailability, protection of active ingredients, improved stability, and easy dispensing of liquid oral formulations. Rapid growth of the Indian generics coupled with rising healthcare expenditure is positively impacting the sales of CMC. Leading pharmaceutical companies are increasingly utilizing CMC to gain compliance with stringent regulatory norms.

Personal Care Generates Robust Opportunities

India's personal care has witnessed a massive boom over the past decade driven by factors such as increasing population, growing middle-class, rising living standards, expanding retail landscape and greater exposure to global personal care brands. Rapid growth in skin care, hair care, color cosmetics, oral hygiene and other personal care categories has fueled the demand for functional additives and thickeners such as CMC. Attributes like thickening capability, emulsion stabilization, viscosity enhancement, film formation and water retention properties make CMC ideal for use in various personal care products including creams, lotions, gels, shampoos, conditioners and toothpastes. Support from government efforts to promote 'Make in India' further boost domestic manufacturing of personal care goods incorporating CMC.

Paints Exhibiting Healthy Demand Trends

India's paints has emerged as a major end-user of CMC in recent times. Growth in infrastructure, real estate construction, automotive and industrial sectors has majorly driven paint consumption across India. As a critical additive in water-based architectural and industrial paints & coatings, CMC helps to improve gloss, leveling, smoothness, adhesion and substrate wetting. It also enhances stability of paint emulsions while lowering production costs. Staggering investment in smart cities, roadways, railways and expansion of manufacturing industries will continue providing a fillip to the paints and thereby drive CMC uptake. Additionally, remodeling and renovation activities are stimulating demand for decorative paints where CMC sees wide usage as a latex stabilizer and thickening agent.

Oil & Gas Exploration & Production Augmenting Consumption

The Indian oil & gas is currently undergoing massive transformation with government initiatives to boost domestic production and reduce import reliance. Expanding oil & gas exploration & production (E&P) activities are opening up new opportunities for CMC consumption. In oilfield applications, CMC is primarily used as a viscosity control additive, fluid loss control agent and filtration control polymer in drilling fluids. It helps improve borehole stability, shale inhibition and lubricity along with enhancing suspension of solid particles. Besides upstream E&P, growing natural gas transportation infrastructure in India is majorly propelling the demand for CMC which aids in corrosion inhibition, scale prevention and paraffin dispersion in pipelines.

Rising Manufacturing Base Fuels Domestic Production

Backed by favorable government policies and availability of low-cost manpower, India has been rapidly emerging as a global manufacturing hub for various industries. Booming domestic manufacturing of end-use products coupled with import substitution has majorly benefitted domestic CMC producers over the past decade. Leading Indian chemical companies are extensively investing in capacity expansions to cater to growing local demand as well as develop export s. Owing to advantages like cost-competitiveness, proximity to major end-use industries and assured raw material supply, the India CMC production capacity is expected to surge further over the coming years.

To conclude, propelled by widening end-use applications and expansion of manufacturing industries, the India CMC is anticipated to continue marching along an upward trajectory over the next several years. Growing prominence of India as an export hub for end-user industries will further amplify the consumption of CMC across the nation. Ongoing investments by domestic producers to augment capacities are aimed at fulfilling this burgeoning demand from an array of sectors. Mounting industrialization, rising standards of living and supportive government policies are projected to accelerate India's domination as one of the fastest growing s for CMC globally.

Get more insights on this topic: https://www.trendingwebwire.com/the-rise-of-india-carboxymethyl-cellulose-cmc/

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement. (LinkedIn - https://www.linkedin.com/in/priya-pandey-8417a8173/)

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it