Understanding In-Mold Labeling

In-mold labeling is a cutting-edge process where pre-printed labels are inserted into a mold and fused with the product during the molding process. This integration results in a fully decorated item straight out of the mold, eliminating the need for post-production labeling. The result is a product that combines high-quality graphics with robust functionality.

Benefits of In-Mold Labeling

Durability: Labels applied through IML are highly resistant to wear and tear. Unlike traditional labels, they won’t peel, scratch, or fade, ensuring that the product maintains its appearance and brand integrity over time.

Superior Aesthetics: IML allows for vibrant, high-resolution graphics and complex designs, providing a premium look that enhances shelf appeal. The seamless integration of the label ensures a sleek, polished finish.

Cost-Effective: By merging the labeling and molding processes, IML reduces production steps and associated costs. This efficiency not only speeds up the manufacturing process but also lowers labor and material expenses.

Environmental Advantages: IML is an eco-friendly option as it eliminates the need for additional adhesives and reduces waste from traditional labeling methods. This sustainable approach aligns with the increasing demand for environmentally responsible packaging.

Versatility: DKM’s IML technology is versatile, applicable to a wide range of materials and products. From food containers and consumer goods to industrial components, IML can be adapted to various applications, offering consistent quality and performance.

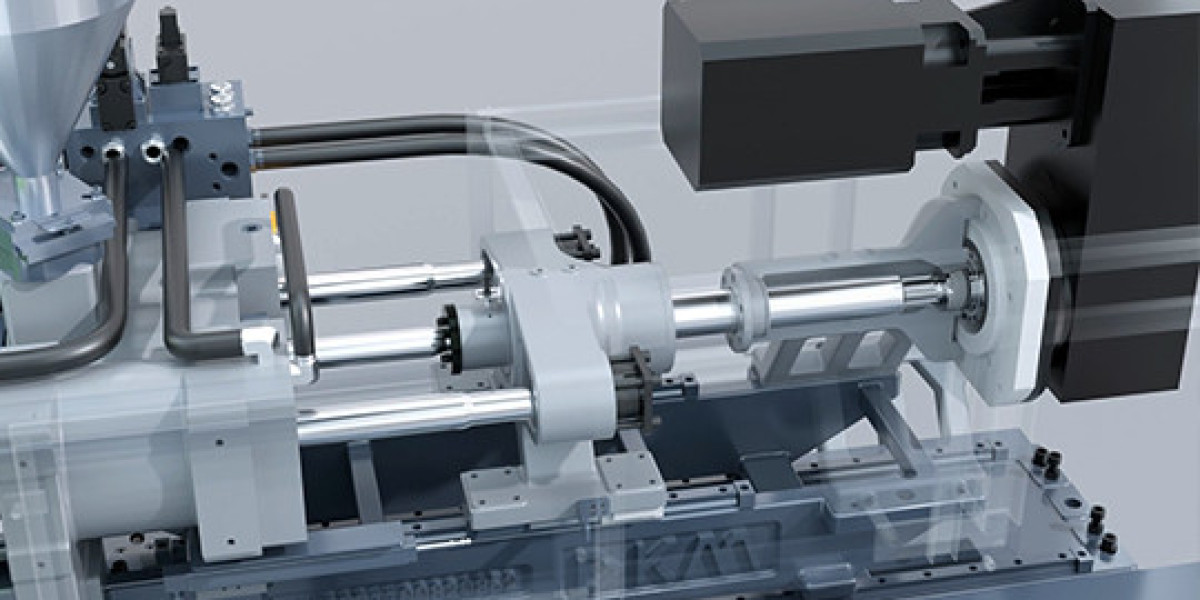

DKM’s Advanced IML Solutions

DKM is at the forefront of in-mold labeling technology, providing innovative solutions tailored to meet the diverse needs of our clients. Our IML systems are designed to deliver precision, reliability, and efficiency, ensuring top-quality results for every project.

Key Features of DKM’s IML Technology

- Precision Engineering: Our IML machines are built for exact label placement, guaranteeing uniformity and high-quality finishes across all products.

- Ease of Use: With user-friendly controls and intuitive interfaces, DKM’s IML systems are easy to operate and maintain, reducing downtime and maximizing productivity.

- Customizable Options: We understand that each project has unique requirements. DKM offers customizable IML solutions to fit your specific needs, ensuring optimal performance and results.

Applications of DKM’s IML Technology

- Food and Beverage Packaging: Enhance product presentation and durability for containers, lids, and bottles, ensuring compliance with food safety standards.

- Consumer Goods: Create appealing, durable labels for household items, toys, and personal care products that withstand daily use.

- Industrial Parts: Improve the functionality and branding of industrial components with robust, high-quality labels that endure harsh conditions.

Why Choose DKM?

At DKM, innovation and quality are at the heart of everything we do. Our in-mold labeling solutions are backed by extensive research and development, ensuring that our clients receive the most advanced and reliable technology available. We are dedicated to providing exceptional customer service and customized solutions to meet your specific needs.