In the realm of modern insulation, efficiency is the name of the game. As the demand for energy efficient homes rises across the nation, the spotlight is on insulation solutions that deliver optimal results. One method that has gained significant traction is blown-in insulation, and at the heart of this efficiency lies the choice of the right blown-in insulation machine. Join us on an insightful journey as we explore the intricacies of selecting the perfect machine to propel us into the era of an Insulation Nation.

The Rise of Insulation Nation

As environmental consciousness grows and energy efficiency becomes a priority, the concept of an Insulation Nation takes center stage. Blown in insulation emerges as a key player in this movement, offering a versatile and effective solution for both residential and commercial spaces. Choosing the right blown in insulation machine becomes pivotal in unlocking the full potential of this insulation method.

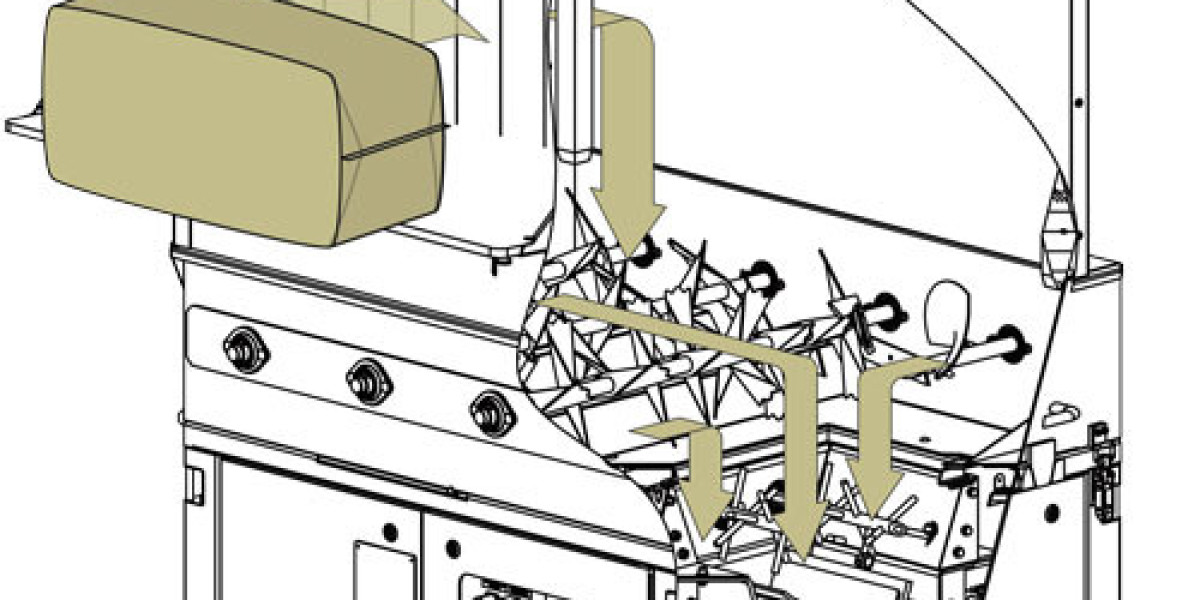

Understanding Blown In Insulation

Before delving into the machinery, its crucial to understand the essence of blown in insulation. Comprising loose fill materials such as fiberglass, cellulose, or mineral wool, this insulation type excels in filling gaps and voids seamlessly. Its adaptability to various spaces, including attics and walls, makes it a preferred choice for builders and homeowners alike.

Versatility in Material Choices

One of the first considerations when selecting a blown-in insulation machine is the type of material it accommodates. Each material has its unique properties, influencing factors such as thermal resistance, fire resistance, and environmental impact. Whether opting for the traditional efficiency of fiberglass or the eco friendly nature of cellulose, the machine should align with the chosen material for optimal performance.

Capacity and Output

Efficiency is closely tied to capacity and output. The right blown-in insulation machine should align with the scale of the project at hand. Whether insulating a small residential attic or a large commercial space, the machine's capacity to process and distribute insulation material efficiently is a critical factor in achieving uniform coverage and desired thermal performance.

Ease of Operation and Portability

In the fast-paced world of construction and insulation projects, time is of the essence. Opting for a blown-in insulation machine that is user-friendly and portable can significantly enhance efficiency. The ease of operation ensures that both seasoned professionals and DIY enthusiasts can maximize the benefits of blown-in insulation without unnecessary complications.

Innovative Technological Features

The landscape of insulation machinery is evolving, and innovative technological features can elevate efficiency to new heights. From advanced control systems for material flow to smart sensors that optimize coverage, investing in a machine with cutting-edge technology ensures a seamless insulation process and enhanced project outcomes.

Durability and Longevity

A machine's durability is a direct contributor to long-term efficiency. Investing in a robust and reliable blown-in insulation machine ensures that it can withstand the rigors of continuous use, minimizing downtime and maintenance costs. Durability guarantees that the machine remains a steadfast ally in insulation projects for years to come.

Cost Considerations and Return on Investment

While efficiency is paramount, the economic aspect cannot be overlooked. Assessing the initial cost of the machine against its long term benefits and return on investment is a strategic approach. A well-chosen blown-in insulation machine strikes a balance between affordability and performance, making it a wise investment for contractors and homeowners alike.

Industry Standards and Certifications

Quality assurance is a crucial aspect of the insulation process. Opting for a blown in insulation machine that adheres to industry standards and certifications ensures that the insulation meets or exceeds regulatory requirements. This commitment to quality not only enhances efficiency but also provides peace of mind regarding the longevity and effectiveness of the insulation.

Environmental Impact

In the era of Insulation Nation, sustainability is a key consideration. Choosing a blown in insulation machine that aligns with environmental standards and promotes the use of eco friendly insulation materials contributes to a more sustainable and energy efficient future. This conscientious choice resonates with the broader goals of creating a greener and healthier living environment.

Conclusion

In the journey towards an Insulation Nation, the right blown in insulation machine serves as a catalyst for efficiency, sustainability, and optimal performance. As builders, contractors, and homeowners embrace the benefits of blown-in insulation, the careful selection of the right machine becomes a defining factor in realizing the vision of energy efficient, comfortable, and environmentally conscious spaces. With the right machine in hand, we pave the way towards a future where every structure, big or small, is a testament to the efficiency and efficacy of blown-in insulation in our Insulation Nation.