Introduction

Polyethylene (PE) film, commonly referred to as polythene film, is a versatile and widely used material in various industries due to its durability, flexibility, and cost-effectiveness. This article provides an in-depth look at the different types of PE films, their applications, and addresses frequently asked questions about this essential material. We will also highlight some key players in the industry, including Polythene film manufacturers and the rising trend of biodegradable options.

Understanding PE Film

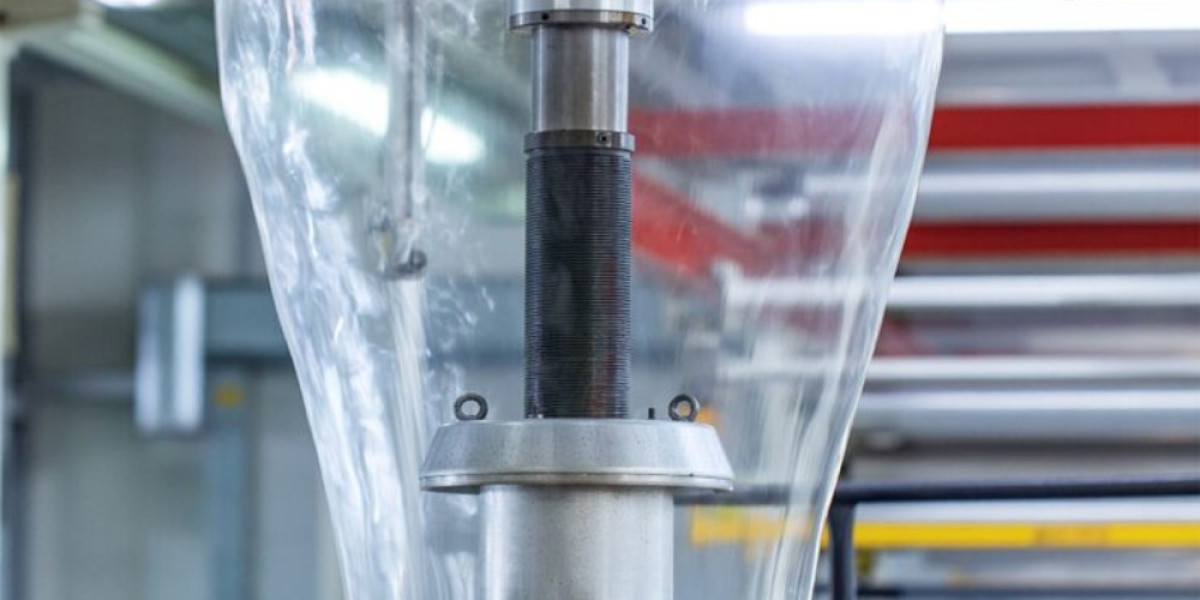

What is PE Film?

PE film is a thin plastic material made from polyethylene, a polymer produced by the polymerization of ethylene. It is known for its excellent mechanical properties, chemical resistance, and low cost, making it a popular choice for a variety of applications. PE film is available in different forms, including low-density polyethylene (LDPE) and high-density polyethylene (HDPE), each offering distinct characteristics.

Types of PE Film

Low-Density Polyethylene (LDPE) Film

LDPE film is characterized by its flexibility, transparency, and resilience. It is often used for applications that require durability and resistance to impact and moisture. Common uses of LDPE film include:

Applications of PE Film

PE film is employed across various industries due to its adaptability and range of properties. Here are some of the primary applications:

Packaging Industry

PE film is a cornerstone of the packaging industry, used in a myriad of forms such as bags, wraps, and pouches. Its ability to protect products from moisture, contamination, Polythene film manufacturers uk, consumer goods, and industrial products.

Agriculture

In agriculture, PE film is used to enhance crop yields and protect plants. Applications include greenhouse films, mulch films, and silage wraps, which help in controlling the growing environment and preserving fodder.

Construction

PE film is used in construction for moisture barriers, insulation backing, and as protective coverings. Its durability and resistance to chemicals and UV light make it suitable for demanding environments.

Medical and Healthcare

In the medical sector, PE film is used in the production of disposable gloves, gowns, and packaging for sterile products. Its impermeability and resistance to chemicals ensure the safety and integrity of medical supplies.

Conclusion

PE film remains an essential material across various industries due to its versatility, durability, and cost-effectiveness. With advancements in biodegradable options, it is also contributing to more sustainable packaging solutions. Understanding the different types of PE films and their specific applications helps businesses and consumers make informed choices to meet their needs while supporting environmental sustainability.

For those seeking reliable sources, polythene film manufacturers in the UK and India offer a wide array of high-quality products. As the industry evolves, embracing eco-friendly alternatives like Biodegradable polythene film will play a crucial role in reducing the environmental impact of plastic packaging.

Frequently Asked Questions (FAQs)

Q1: Who are the leading polythene film manufacturers?

Leading polythene film manufacturers include companies such as ExxonMobil, Dow Chemical, and Berry Global. In the UK, notable manufacturers include RPC Group and Polystar Plastics, known for their high-quality polythene film products.

Q2: What are biodegradable polythene films?

Biodegradable polythene films are designed to decompose more quickly than traditional PE films when exposed to environmental conditions such as moisture, heat, and microbial activity. These films help reduce the long-term environmental impact of plastic waste.

Q3: Are biodegradable polythene films as durable as traditional PE films?

Biodegradable polythene films are generally designed to perform similarly to traditional PE films in terms of strength and flexibility during their intended use. However, their lifespan is shorter as they are engineered to break down more rapidly after disposal.