Introduction:

Polyethylene (PE) film is a versatile and widely used material in various industries for packaging, insulation, and protective applications. Understanding the basics of PE film, including its composition, properties, and applications, is essential for businesses seeking reliable packaging solutions. In this article, we explore the fundamentals of PE film, its environmental implications, and address common questions about its usage. Additionally, we highlight reputable Polythene film manufacturers in the UK and discuss the emergence of biodegradable polythene film options.

Understanding the Basics of PE Film:

Composition and Structure:

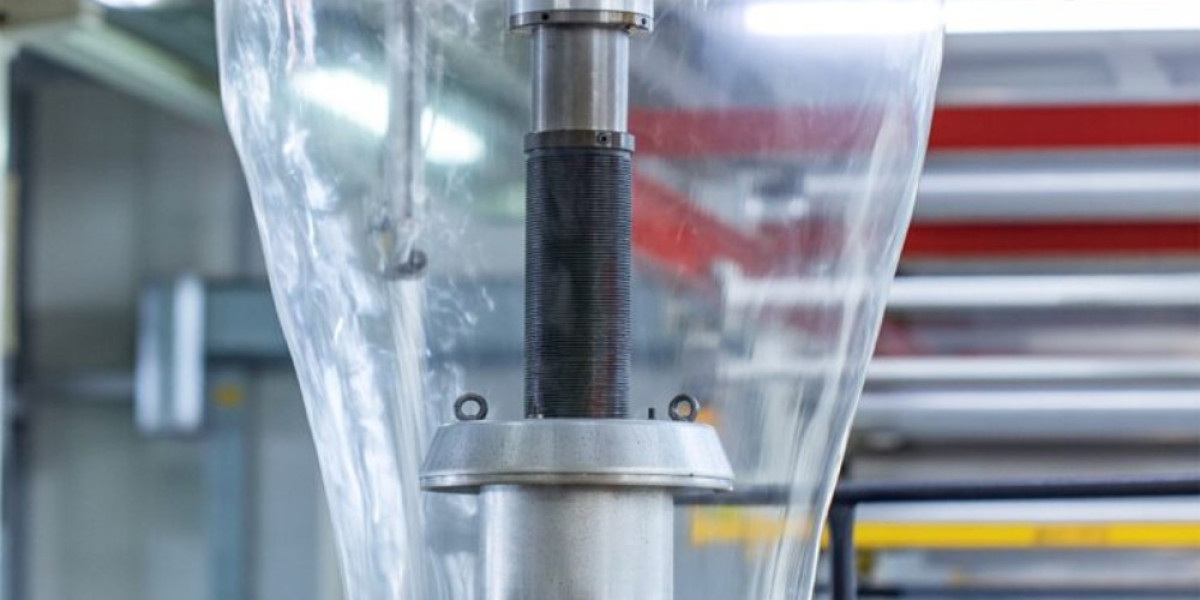

PE film is a type of plastic film composed primarily of polyethylene, a thermoplastic polymer derived from ethylene monomers. It is produced through a process called polymerization, where ethylene molecules are chemically bonded to form long chains of polyethylene. PE film can vary in density, thickness, and molecular structure, influencing its mechanical and barrier properties.

Properties and Characteristics:

PE film exhibits several key properties that make it suitable for a wide range of applications. These include flexibility, durability, chemical resistance, and moisture barrier properties. Polythene film manufacturers uk, and it is available in various grades, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE).

Applications of PE Film:

PE film finds extensive use in packaging, where it is employed for wrapping, sealing, and protecting goods during storage and transportation. It is used in various industries, including food and beverage, agriculture, pharmaceuticals, construction, and retail. Common applications include shrink wrap, stretch film, bags, pouches, and agricultural mulch film.

Environmental Considerations:

The widespread use of PE film has raised concerns about its environmental impact, particularly regarding plastic pollution and waste management. Traditional PE film is non-biodegradable and can persist in the environment for hundreds of years, contributing to litter and marine debris. However, advancements in technology have led to the development of biodegradable and compostable alternatives, offering more sustainable options for packaging and reducing environmental harm.

Conclusion:

PE film is a versatile material with a wide range of applications in packaging and beyond. Understanding its composition, properties, and environmental considerations is crucial for making informed decisions about its usage. As businesses seek more sustainable alternatives, the emergence of Biodegradable polythene film options offers promising solutions to address plastic pollution and promote environmental stewardship. By partnering with reputable polythene film manufacturers in the UK, businesses can access high-quality PE film products tailored to their specific needs while contributing to sustainability goals and reducing environmental impact.

Frequently Asked Questions (FAQs):

Q1: Who are some reputable polythene film manufacturers in the UK?

A: The UK is home to several reputable polythene film manufacturers, including [Insert Polythene Film Manufacturers UK]. These manufacturers produce a wide range of PE film products, catering to diverse industry needs and quality standards.

Q2: What are the benefits of using biodegradable polythene film?

A: Biodegradable polythene film offers environmental benefits by breaking down naturally into harmless substances, such as water, carbon dioxide, and biomass, under specific conditions. It reduces reliance on fossil fuels, minimizes plastic pollution, and supports efforts to transition to more sustainable packaging solutions.

Q3: How does the recyclability of PE film compare to other packaging materials?

A: PE film is recyclable, but its recyclability can vary depending on factors such as material composition, contamination, and collection infrastructure. While recycling rates for PE film have improved in recent years, challenges remain in achieving widespread collection and processing of post-consumer film waste.

Q4: What are some innovative applications of PE film in modern industries?

A: In addition to traditional packaging applications, PE film is increasingly being used in innovative ways across industries. This includes applications such as solar panels encapsulation, greenhouses, medical devices, and protective coatings. Advancements in film technology continue to expand the potential uses of PE film in diverse sectors.