Introduction:

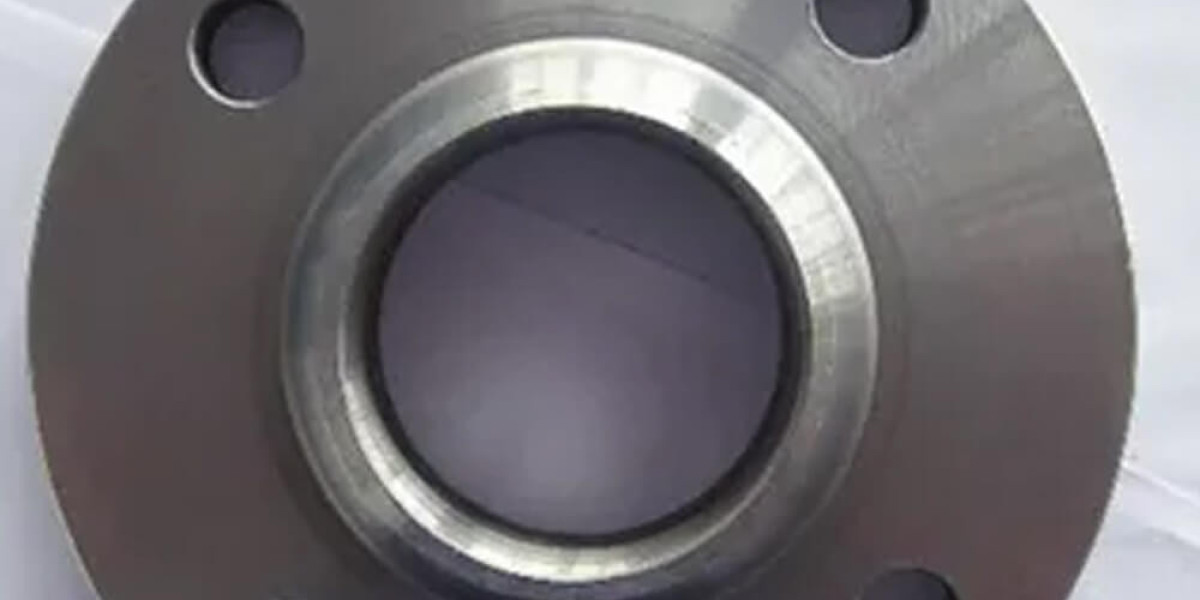

Stainless Steel 310S Flanges: The Unsung Heroes in Industrial Excellence

In the world of industrial applications, where durability, corrosion resistance, and high-temperature stability are paramount, Stainless Steel 310S flanges emerge as unsung heroes. These robust components play a crucial role in connecting pipes, valves, and other equipment, ensuring a seamless flow of materials in various industrial processes. Let's delve into the unique attributes that make Stainless Steel 310S flanges a standout choice in the realm of engineering excellence.

1. Corrosion Resistance: A Shield Against Environmental Threats

Stainless Steel 310S is renowned for its exceptional corrosion resistance properties. The alloy contains high levels of chromium and nickel, forming a protective layer that shields the flanges from corrosive elements. This inherent corrosion resistance makes Stainless Steel 310S flanges ideal for applications in harsh environments, such as chemical processing plants and offshore drilling platforms.

2. High-Temperature Stability: Thriving in Intense Heat

One of the standout features of Stainless Steel 310S flanges is their ability to withstand extreme temperatures. With a maximum operating temperature of around 1900°F (1038°C), these flanges excel in applications where exposure to high heat is inevitable. Industries such as petrochemical, furnace manufacturing, and heat treatment plants benefit significantly from the stable performance of Stainless Steel 310S flanges under intense heat conditions.

3. Strength and Durability: The Backbone of Industrial Infrastructure

Stainless Steel 310S flanges are crafted with precision, ensuring a high level of mechanical strength and durability. This robustness is particularly crucial in industries that demand reliability and longevity from their equipment. Whether used in power generation facilities or oil refineries, Stainless Steel 310S flanges serve as the backbone of industrial infrastructure, providing a reliable and resilient connection between various components.

4. Versatility in Applications: Adapting to Diverse Industries

The versatility of Stainless Steel 310S flanges extends across a wide spectrum of industries. From chemical processing to oil and gas, from aerospace to food and beverage, these flanges find applications in diverse sectors. Their adaptability to different environments and operational conditions makes them a preferred choice for engineers and project managers seeking a reliable and versatile solution.

5. Ease of Fabrication: Streamlining Installation Processes

Fabricating and installing Stainless Steel 310S flanges is a streamlined process, thanks to the alloy's excellent machinability. This ease of fabrication not only reduces installation time but also enhances the overall efficiency of industrial projects. Whether it's a new construction or a maintenance upgrade, Stainless Steel 310S flanges contribute to a smoother and more cost-effective implementation.

Conclusion:

In the intricate tapestry of industrial components, Stainless Steel 310S flanges stand out as resilient, versatile, and reliable connectors. Their corrosion resistance, high-temperature stability, strength, and ease of fabrication make them indispensable in a multitude of applications. As industries continue to evolve, Stainless Steel 310S flanges remain steadfast, silently ensuring the seamless flow of materials that fuels progress and innovation.

For more Information

Visit website:

Email: info@nascentgroup.in

Contact: 8779038854