Introduction

Isopropyl alcohol (IPA), also known as rubbing alcohol, is a widely used chemical compound with diverse applications in industries ranging from pharmaceuticals and healthcare to cosmetics and manufacturing. The demand for isopropyl alcohol has surged significantly due to its various uses in disinfectants, sanitizers, cleaning agents, and as a solvent in numerous industrial applications. Establishing an isopropyl alcohol manufacturing plant presents a lucrative business opportunity, especially with the rising demand driven by hygiene awareness, particularly in the post-pandemic era. This detailed Isopropyl Alcohol Manufacturing Plant Project Report aims to provide comprehensive insights into setting up an isopropyl alcohol manufacturing plant. The report covers the key aspects of the manufacturing process, required raw materials, equipment, regulatory requirements, market analysis, and financial considerations.

Market Demand for Isopropyl Alcohol

Isopropyl alcohol has diverse applications across multiple sectors. The growing demand for IPA is driven by several factors:

Pharmaceutical and Healthcare Industry: IPA is widely used as a disinfectant and antiseptic in healthcare settings. It is employed for cleaning and sanitizing surfaces, medical equipment, and as an ingredient in hand sanitizers and wipes. The surge in hygiene awareness, especially after the COVID-19 pandemic, has boosted the demand for IPA globally.

Cosmetic Industry: IPA is an essential solvent in the formulation of cosmetic products such as lotions, perfumes, and deodorants. It is also used in the production of nail polish removers and as a solvent in hair and skin care products.

Industrial Applications: Isopropyl alcohol serves as a solvent for paints, coatings, and inks, making it highly demanded in industries such as automotive, manufacturing, and construction. It is also used as a cleaning agent in industries like electronics, optics, and automotive manufacturing.

Household and Commercial Cleaning: IPA is a common ingredient in cleaning products used for removing grease, oils, and other contaminants. It is popular for household cleaning, automotive detailing, and electronics cleaning due to its fast evaporation rate and ability to disinfect surfaces effectively.

Fuel and Solvent: IPA is also used as a solvent in various chemical processes and formulations. It is sometimes blended with fuels to improve combustion in engines and used as a cleaning agent in petrochemical industries.

Given the extensive use of IPA across these sectors, setting up a manufacturing plant can be a profitable venture, especially if you cater to multiple industries simultaneously.

Get a Free Sample Report with Table of Contents@

Raw Materials for Isopropyl Alcohol Manufacturing

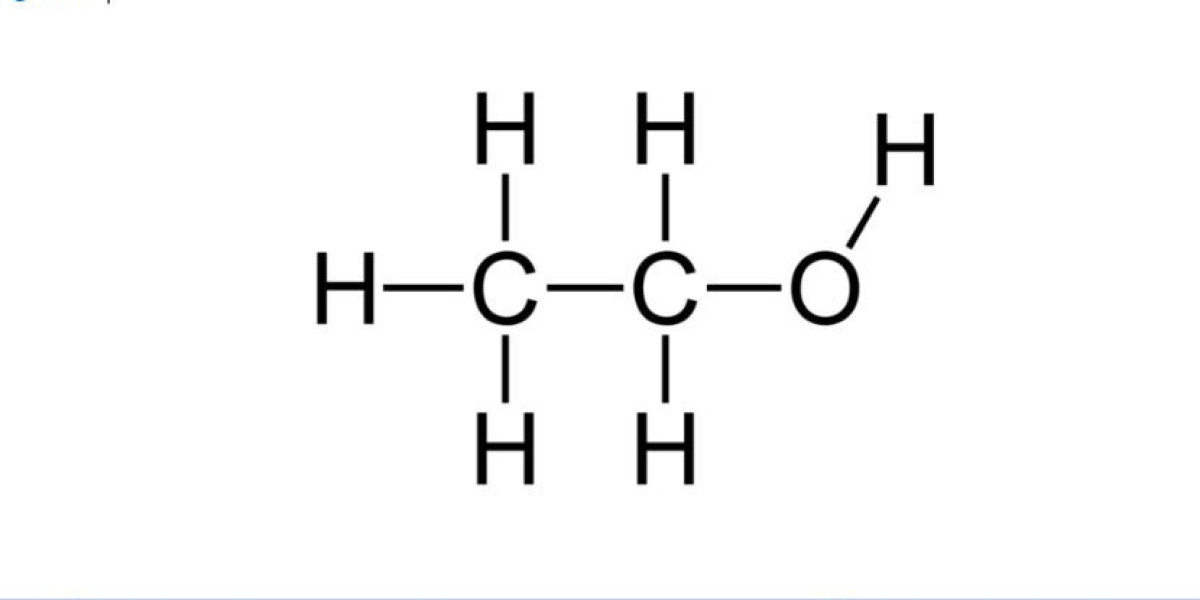

The production of isopropyl alcohol primarily involves the conversion of propylene, a key raw material, into IPA through chemical reactions. The main raw materials required for IPA production are:

Propylene: Propylene is the core raw material for producing isopropyl alcohol. It is a by-product of petroleum refining and natural gas processing. Propylene is available in large quantities from refineries and petrochemical plants, making it easily accessible for IPA manufacturing.

Hydrogen: Hydrogen is another important raw material used in the hydrogenation process to convert propylene into isopropyl alcohol. Hydrogen is typically obtained from natural gas or through the electrolysis of water.

Catalysts: Catalysts are used to accelerate the chemical reactions during the manufacturing process. In IPA production, acidic or basic catalysts may be employed depending on the reaction type.

Solvents: Solvents may be needed in the production process to dissolve certain reactants or facilitate separation of by-products during the distillation phase.

Water: Water is essential in the production of IPA, especially in the distillation and separation processes, where water helps purify the product.

Isopropyl Alcohol Manufacturing Process

The production of isopropyl alcohol involves several stages, primarily focusing on the conversion of propylene into IPA. Below is an overview of the key steps involved:

1. Hydration of Propylene

The first step in the manufacturing process is the hydration of propylene to produce isopropyl alcohol. This is done through either a direct or indirect hydration process:

Direct Hydration: In this method, propylene reacts directly with water in the presence of an acid catalyst (typically phosphoric acid) at high temperature and pressure. The reaction results in the production of isopropyl alcohol.

Indirect Hydration (Sulfation Process): In this method, propylene first reacts with sulfuric acid to form propyl sulfate, which is then hydrolyzed (reacted with water) to produce isopropyl alcohol.

2. Purification

After the hydration process, the crude isopropyl alcohol is subjected to purification. The product may contain impurities like water, unreacted propylene, and other by-products. Purification is carried out using:

Distillation: The crude product is distilled to separate isopropyl alcohol from other volatile components. This process removes water, residual propylene, and other impurities to obtain high-purity IPA.

Absorption: In some cases, absorption techniques are used to remove any remaining impurities.

3. Final Separation and Quality Control

Once the IPA is purified, it undergoes final separation processes to ensure that it meets the required specifications for purity, concentration, and quality. The product is then tested for various parameters such as strength, pH, and presence of residual solvents. Quality control measures are implemented to ensure that the final product is free from contaminants and meets industry standards.

4. Packaging

After testing and ensuring the product's quality, the final isopropyl alcohol is packaged in containers such as bottles, drums, or bulk tanks, depending on the demand and market. Packaging is an important step, as it helps preserve the quality of the product and ensures safe transportation and storage.

Required Equipment for Isopropyl Alcohol Manufacturing

To set up an isopropyl alcohol manufacturing plant, various equipment and machinery are necessary to ensure efficient production and high-quality output. Some of the key equipment required for IPA manufacturing includes:

Reactor Vessels: These are large containers where the reaction of propylene with water or sulfuric acid takes place under controlled temperature and pressure conditions.

Distillation Columns: Distillation columns are used for separating the isopropyl alcohol from other components, ensuring high purity in the final product.

Heat Exchangers: These are used to control the temperature during the distillation and reaction processes, ensuring the right conditions for optimal reactions.

Absorption Units: These are used for removing impurities and residual components from the product stream.

Storage Tanks: Storage tanks are necessary to hold the raw materials, intermediate products, and final IPA before packaging.

Filling and Packaging Machines: These machines are used to fill containers and package the IPA for distribution.

Quality Control Testing Equipment: Laboratories and equipment for testing the purity, concentration, and quality of the final product.

Regulatory Compliance and Safety Standards

Like all chemical manufacturing plants, the production of isopropyl alcohol is subject to various safety and regulatory standards. These regulations ensure the safety of workers, the environment, and consumers. Key regulatory requirements include:

Environmental Regulations: The production process should comply with environmental guidelines regarding waste management, emissions, and water treatment. Effluents and emissions should be treated before being released into the environment.

Safety Standards: IPA is highly flammable, and strict safety measures must be in place to prevent accidents. Proper storage, handling, and transportation protocols should be followed.

Quality Standards: Manufacturers must ensure their product complies with industry standards, such as the U.S. Pharmacopeia (USP) or European Pharmacopoeia (EP) for pharmaceutical-grade IPA.

Workplace Safety: Manufacturing facilities should adhere to occupational health and safety standards to protect employees from exposure to hazardous materials.

Financial Considerations

Setting up an isopropyl alcohol manufacturing plant requires a significant investment. Key financial aspects to consider include:

Capital Investment: The cost of land, construction, and equipment setup is substantial. The capital investment required for a medium-sized plant can run into several million dollars.

Operating Costs: Raw material costs, energy consumption, labor, and maintenance expenses will contribute to the ongoing operational costs of the plant.

Market Pricing: The price of isopropyl alcohol can vary based on market demand, purity levels, and production volume. Manufacturers need to carefully consider their pricing strategy to remain competitive.

Return on Investment (ROI): A well-optimized production plant with access to key markets can achieve good ROI within a few years, depending on the scale and efficiency of operations.

FAQs

Q1: What is the primary raw material for isopropyl alcohol production?

Propylene is the primary raw material used for manufacturing isopropyl alcohol.

Q2: What industries use isopropyl alcohol?

IPA is used in pharmaceuticals, healthcare, cosmetics, manufacturing, automotive, and household cleaning industries.

Q3: Is isopropyl alcohol hazardous?

Yes, isopropyl alcohol is flammable and should be handled with care. Safety precautions must be followed during storage and handling.

Q4: Can I manufacture isopropyl alcohol on a small scale?

Small-scale production is possible, but large-scale production is typically more cost-effective due to economies of scale.

Q5: What are the key safety concerns in an IPA manufacturing plant?

Key safety concerns include fire hazards, chemical exposure, and proper waste disposal. Adhering to safety standards is essential.

Related Reports

https://www.expertmarketresearch.com.au/reports/australia-music-market

https://www.expertmarketresearch.com.au/reports/australia-oil-and-gas-upstream-market

https://www.expertmarketresearch.com.au/reports/australia-online-gambling-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au