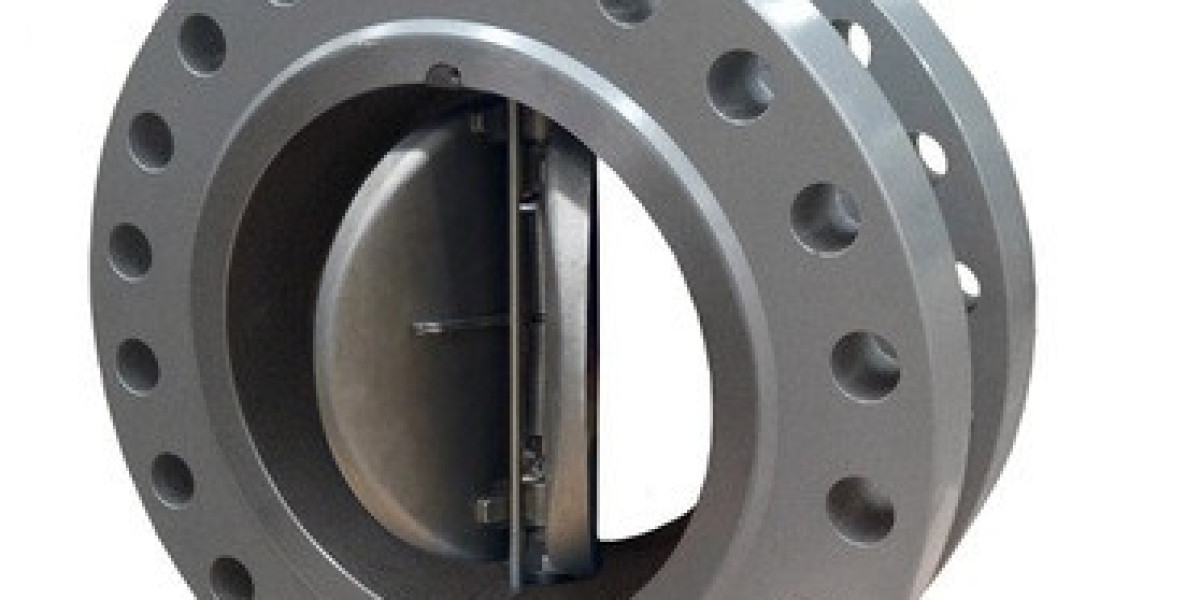

South American Valve is a well-known Dual Plate Check valve manufacturer in Brazil. A dual plate check valve is a non-return valve characterized by preventing fluid backflow but allowing the passage of fluids in one direction. It is made up of spring-loaded plates or discs pivoted on a central hinge pin. In the case of fluid movement in the forward direction, the pressure forces the plates to swing open and pass without any obstruction. Springs move the plates to shut off when the flow reversal or stoppage happens, sealing on the valve seat with no chance of backflow. The design is highly responsive to changes in directions of flow; it can therefore be applied for water supply systems, oil and gas pipelines, and various industrial processes.

South American Valve is one of the leading Dual Plate Check valve manufacturer in Brazil. It has various advantages over the traditional single-disc check valves. It has compact and lightweight designs; thus, little space is occupied during installation and is quite less in weight, especially for large-scale industrial systems. The two-plate design gives a balanced closure for the valve that minimizes the impact forces and wear on the valve components, therefore providing longer service life for the valve. This valve further offers a low-pressure drop along with efficient flow characteristics, which support system performance as well as energy efficiency in using it. The versatility and robust configuration of the dual plate check valve make it highly useful for the prevention of backflow in most kinds of fluid handling systems.

How does it work?

The dual-plate check valve works with two spring-loaded plates swing around a central hinge pin. Forward flow during operation will push the two plates open, allowing fluid to flow at low resistance, but if the flow is halted or reversed, then pressure .

These springs are used to push the plates rapidly into position to close against the valve seat to prevent backflow. The above mechanism ensures that a change in the flow direction is responded to fast and reliably, maintaining unidirectional flow and preventing damage from reverse flow in the system.

Advantages:

● Prevent backflow

● Simple design and operation

● Low maintenance

Industries:

● Chemical Industry

● Pulp and paper Industry

● Marine Industry

● Mining Industry

● Power Generation Industry

● Oil and Gas Industry

● Nuclear Industry

● Petrochemical Industry

● Water Treatment Plants

● Textile Manufacturing Industry

Description:

● Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), DUPLEX AND Super duplex STEEL [ F51, F53,F55 ] Forged Steel A105, A105N, F11, F22, F304, F316, F91] , Alloy20 , Hastelloy ALBR.

● Size- ½” – 80”

● Class-150 – 2500; PN10 – PN-450

● Ends- Threaded, socket weld, butt weld, flanged, lug, wafer.

Visit us to know more:

https://www.southamericanvalve.com/product-category/dual-plate-check-valve/