Introduction:

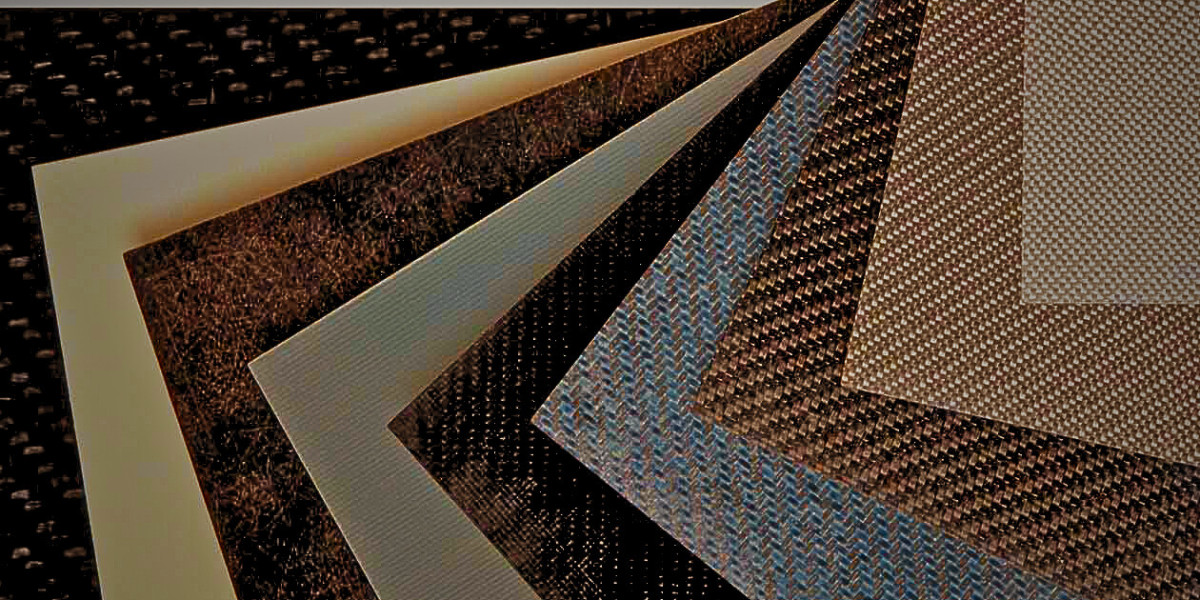

Composites Market have become integral to various industries due to their exceptional strength-to-weight ratio, durability, and versatility. From aerospace to automotive, and from construction to sports equipment, composites are driving innovation and performance. However, the development and adoption of composite materials are significantly influenced by regulations and standards.

Download FREE Sample: https://www.nextmsc.com/composites-market/request-sample

What Are Composite Materials?

Composite materials are engineered substances composed of two or more different materials to create a product with superior properties compared to the individual components. Typically, composites consist of a matrix (resin) and a reinforcement (such as fibers). Common types include fiber-reinforced polymers (FRPs), carbon fiber composites, and glass fiber composites. These materials are used in a wide range of applications due to their high strength, low weight, and resistance to environmental factors.

The Role of Regulations and Standards in Composite Material Development

1. Ensuring Safety and Reliability

Regulations and standards are critical in ensuring the safety and reliability of composite materials used in various applications. In industries such as aerospace, automotive, and construction, where material failure can have severe consequences, adherence to stringent regulations is essential.

- Aerospace Industry: The aerospace sector relies heavily on composites for aircraft and spacecraft components. Regulations from agencies like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) set stringent standards for material performance, testing, and certification. These standards ensure that composite materials can withstand extreme conditions and maintain structural integrity.

- Automotive Industry: In the automotive industry, safety regulations and standards are set by organizations such as the National Highway Traffic Safety Administration (NHTSA) and the European New Car Assessment Programme (Euro NCAP). These standards dictate the performance requirements for composite materials used in vehicle structures, crash components, and safety systems.

Inquire before buying: https://www.nextmsc.com/composites-market/inquire-before-buying

2. Guiding Material Specifications and Testing

Standards provide detailed specifications for the composition, properties, and performance of composite materials. They guide manufacturers in selecting appropriate materials and processes to meet industry requirements.

- ASTM International: The American Society for Testing and Materials (ASTM) publishes standards for composite materials, including specifications for testing methods, material properties, and performance criteria. ASTM standards cover a wide range of composites, from polymer matrix composites to advanced carbon fiber materials.

- ISO Standards: The International Organization for Standardization (ISO) also plays a crucial role in setting global standards for composite materials. ISO standards cover various aspects, including material properties, testing methods, and quality control. These standards ensure consistency and compatibility across international markets.

3. Promoting Innovation and Technological Advancements

Regulations and standards can drive innovation by setting performance benchmarks that encourage the development of new materials and technologies. Manufacturers and researchers are motivated to meet or exceed these standards, leading to advancements in composite material science.

- Performance Benchmarks: Standards often establish performance benchmarks for composite materials, such as strength, durability, and environmental resistance. Meeting these benchmarks drives the development of advanced composites with improved properties and capabilities.

- Research and Development: Compliance with evolving standards encourages ongoing research and development. Manufacturers invest in R&D to create new composite materials that offer enhanced performance, reduced costs, and greater sustainability.

4. Facilitating Market Access and Trade

Regulations and standards play a crucial role in facilitating market access and trade by ensuring that composite materials meet the required quality and performance criteria. Compliance with international standards can open doors to global markets and enable companies to compete effectively.

- Certification and Compliance: Achieving certification to industry standards demonstrates a company's commitment to quality and safety. This certification is often required for market entry and can enhance a company's reputation and competitiveness.

- Harmonization of Standards: International standards help harmonize regulations across different regions, reducing barriers to trade and enabling companies to access global markets more easily. Harmonized standards also ensure that composite materials meet consistent quality and performance criteria worldwide.

Key Regulations and Standards Affecting Composite Materials

1. Aerospace Industry Regulations

- FAA FAR 25: The Federal Aviation Regulations (FAR) Part 25 sets standards for the design and construction of transport category aircraft. It includes requirements for composite materials used in aircraft structures, including testing for flammability, impact resistance, and fatigue.

- EASA CS-25: The European Union Aviation Safety Agency's Certification Specification (CS) 25 outlines requirements for composite materials used in large aircraft. It covers aspects such as material qualification, testing, and inspection.

2. Automotive Industry Standards

- ISO/TS 16949: This standard specifies requirements for a quality management system in the automotive industry. It includes guidelines for the use of composite materials in automotive components, ensuring quality and consistency in production.

- SAE J2030: The Society of Automotive Engineers (SAE) J2030 standard provides guidelines for the use of composite materials in automotive applications. It covers aspects such as material properties, performance testing, and manufacturing processes.

3. Construction Industry Codes

- ASTM C 947: This standard specifies test methods for determining the impact resistance of cementitious coatings used in construction. It is relevant for composites used in building materials and facades.

- ISO 9001: The ISO 9001 standard outlines quality management system requirements applicable to various industries, including construction. It ensures that composite materials used in construction meet quality and performance standards.

4. Marine Industry Regulations

- ISO 12215: This standard provides guidelines for the design and construction of composite materials used in marine applications. It covers aspects such as material properties, testing methods, and design requirements for boat and ship components.

- Lloyd's Register Rules: Lloyd's Register sets rules for the use of composite materials in marine structures, including testing, certification, and quality assurance.

Challenges in Compliance with Regulations and Standards

1. Cost and Complexity

Compliance with regulations and standards can be costly and complex, particularly for smaller manufacturers. Meeting stringent requirements involves investment in testing, certification, and quality control processes, which can impact production costs and timeframes.

2. Evolving Standards

Standards and regulations are continuously evolving to address new challenges and technologies. Keeping up with changes and ensuring ongoing compliance can be challenging for manufacturers, requiring regular updates to processes and materials.

3. Global Variations

Different regions may have varying regulations and standards for composite materials, leading to challenges in harmonizing practices and achieving global compliance. Companies operating in multiple markets must navigate these variations and ensure adherence to local requirements.

4. Technological Advancements

Rapid advancements in composite material technologies may outpace existing standards, creating a gap between current practices and regulatory requirements. Ongoing collaboration between industry stakeholders and standardization bodies is essential to address these gaps and update standards accordingly.

Future Trends in Regulations and Standards

1. Increased Focus on Sustainability

As the demand for sustainable practices grows, regulations and standards are expected to place greater emphasis on the environmental impact of composite materials. Future standards may include requirements for recyclability, reduced carbon footprint, and the use of renewable resources.

2. Integration of Advanced Technologies

The integration of advanced technologies, such as additive manufacturing and nanotechnology, will likely drive updates to existing standards. New regulations may address the unique properties and challenges associated with these technologies.

3. Enhanced Global Harmonization

Efforts to harmonize standards across different regions will continue to facilitate global trade and market access. International collaboration and the development of unified standards will help streamline compliance and reduce barriers for manufacturers.

4. Focus on Performance-Based Standards

There is a growing trend towards performance-based standards that focus on the desired outcomes and performance criteria rather than prescriptive requirements. This approach allows for greater flexibility and innovation in material development while ensuring that performance benchmarks are met.

Conclusion

The impact of regulations and standards on composite material development is profound and multifaceted. These regulations ensure safety, guide material specifications, promote innovation, and facilitate market access. While challenges such as cost, evolving standards, and global variations exist, ongoing advancements and efforts to harmonize practices are shaping the future of composite materials.

As the industry continues to evolve, the role of regulations and standards will remain crucial in driving the development of high-performance composites. By addressing emerging trends and incorporating new technologies, these standards will help ensure that composite materials continue to meet the highest standards of quality, safety, and performance.