LOCANAM FDM 3D PRINTING

3D printing or additive manufacturing rapidly flattering the fast-moving, most desirable means to manufacture custom customer goods. 3D printing has been a well-liked technique of manufacturing prototypes since the 1980s. Further 3D printing establishments have embraced related technologies on divergent names.

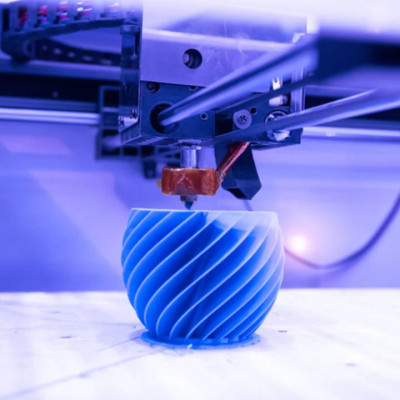

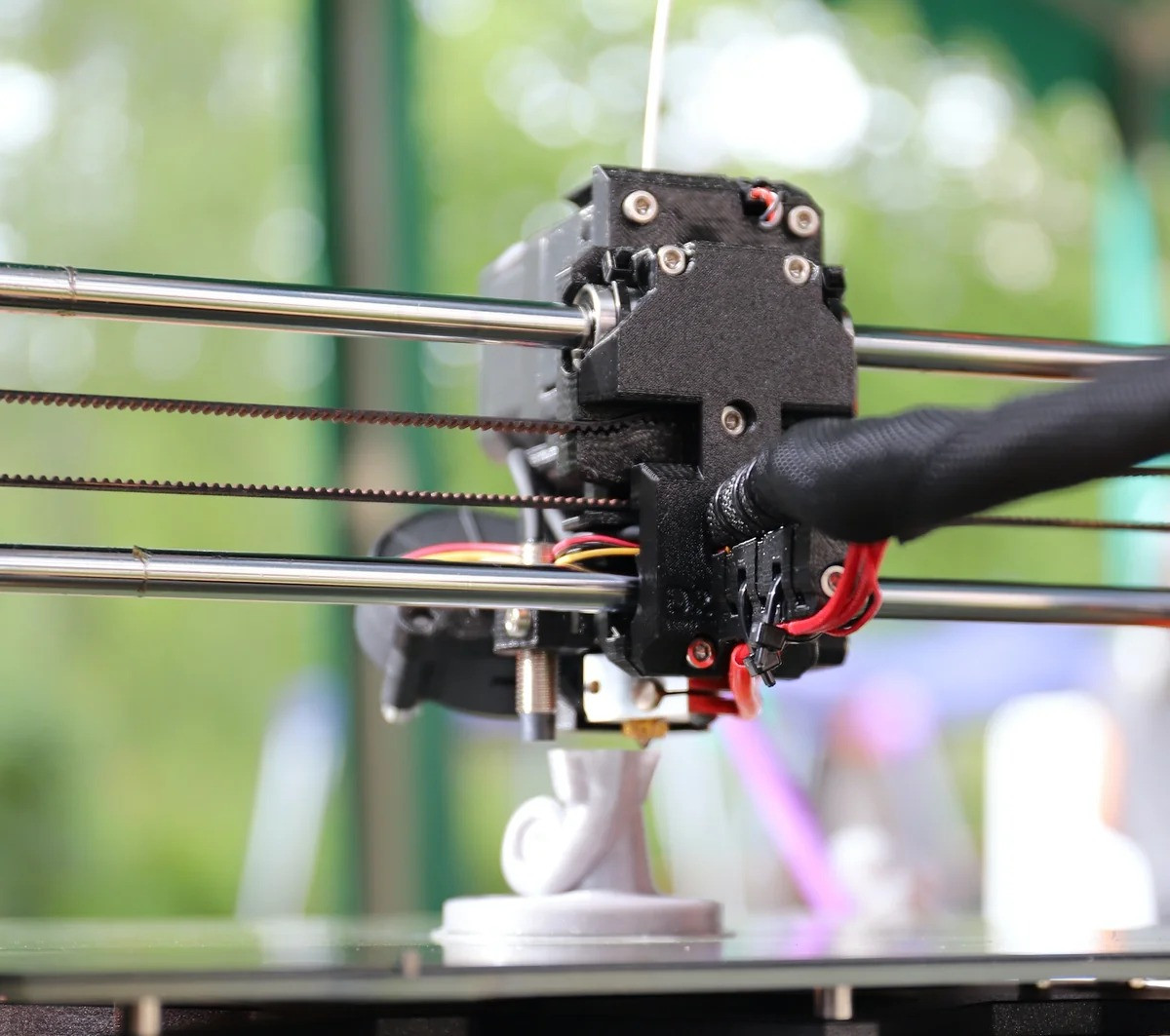

From the various divergent techniques of 3D printing, the most popularly used method is called Fused Deposition Modeling (FDM). FDM printing is a technology that exerts both, one is horizontally and the other is vertically, where an extraction nozzle proceeds above the erect program. Fused Deposition Modeling makes use of a thermoplastic filament that heats up and converts into melt substance then ejected layer by layer, to manufacture a 3-dimensional piece.

Like the other types of 3-D printing, the Fused Deposition Model (FDM) makes use of a digitized outline that is transferred to the 3D printer. There are so many divergent polymers worn, like PLA, ABS, PETG, PEI, and PEEK.

They all get hold of the structure of plastic threads that are suckled from a loop and by way of a nozzle. The fibers are liquefied and suckled upon the bottom is called build platform or table with the base and nozzle, one as well the other is managed by a computer. The data processor exertion by interpreting the substance and its proportion towards the focal that assemble it viable for the nozzle and bottom to accompany.

Simultaneously the nozzle passes over the bottom, the plastic crisps, and becomes rigid, creating a dense pledge with the preceding layer. The print head goes upward in the sequence for the following layer of plastic to be deposited. As consistently, 3D printing is well organized and rapid but the flow it clutches to manufacture the substance and the performances rely on its dimension. Portable substances that are various blockish inches can be manufactured rapidly but sizeable, the further compound substance will clasp lengthy.

FOR MORE - https://www.locanam.com/fdm3dprinting