Introduction:

Polyethylene (PE) film is a versatile packaging material that has revolutionized the way products are protected, preserved, and presented across various industries. From food packaging to industrial applications, PE film offers unparalleled flexibility, durability, and customization options. In this article, we explore the diverse capabilities of PE film, its sustainability features, and address common questions about its usage. Additionally, we highlight prominent Polythene film manufacturers, including those based in the UK, and discuss the emergence of biodegradable polythene film as a sustainable alternative.

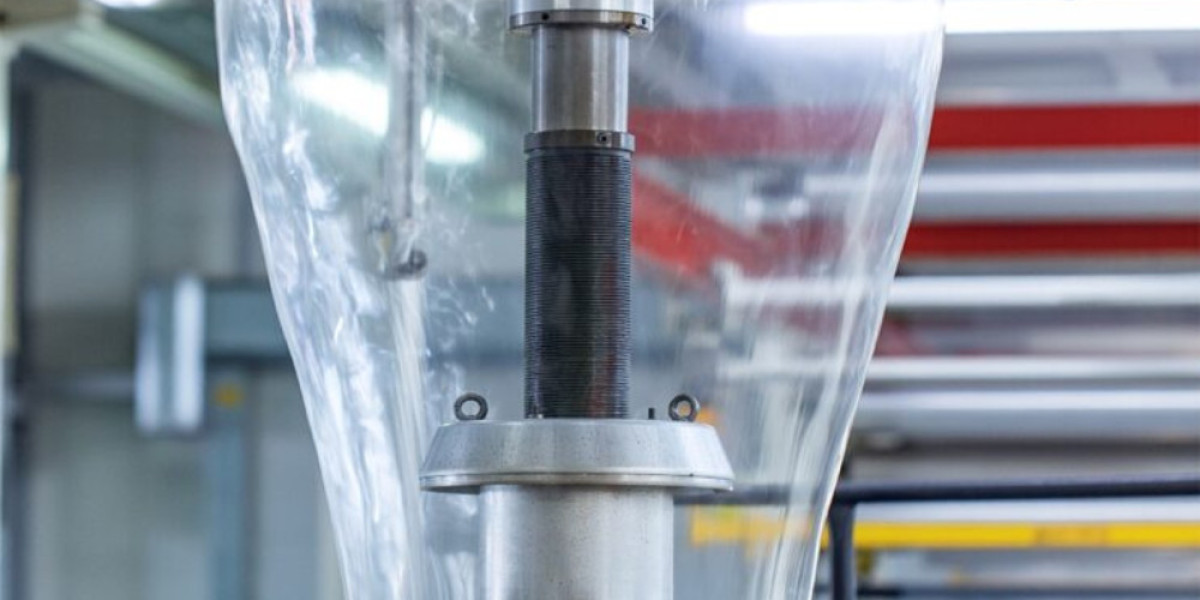

Understanding PE Film:

PE film is a type of plastic film made from polyethylene resin, a polymer widely known for its strength, flexibility, and moisture resistance. It is manufactured through a process of extrusion, where molten polyethylene is formed into thin sheets of varying thicknesses and widths. Biodegradable polythene film, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE), each offering unique properties suited to specific applications.

Versatility and Applications:

Food Packaging:

PE film is extensively used in food packaging due to its excellent barrier properties and compatibility with food contact regulations. It is commonly employed for wrapping fresh produce, meats, dairy products, and frozen foods, providing protection against contamination, moisture loss, and spoilage.

Industrial Packaging:

In industrial settings, PE film serves as a reliable packaging solution for a wide range of products, including electronics, automotive parts, textiles, and building materials. Its ability to conform to various shapes and sizes makes it ideal for wrapping, bundling, and protecting goods during transit and storage.

Agricultural Applications:

PE film plays a crucial role in agriculture for mulching, greenhouse covering, and crop protection. It helps regulate soil temperature, conserve moisture, and control weed growth, thereby improving crop yield and quality. Additionally, UV-stabilized PE film is used for long-term outdoor applications, ensuring durability and performance in harsh environmental conditions.

Medical and Healthcare:

In the medical and healthcare sectors, PE film is utilized for sterile packaging of medical devices, surgical instruments, and pharmaceutical products. Its sterile barrier properties help maintain product integrity and prevent contamination, ensuring patient safety and regulatory compliance.

Conclusion:

PE film stands as a versatile packaging material with a wide range of applications and sustainability features. From food packaging to industrial uses, PE film offers unparalleled flexibility, durability, and environmental benefits. As the demand for sustainable packaging solutions grows, Polythene film manufacturers uk, paving the way for a more sustainable future. By partnering with reputable polythene film manufacturers, businesses can access high-quality products tailored to their specific needs while contributing to environmental stewardship and circular economy practices.

Frequently Asked Questions (FAQs):

Q1: Who are some reputable polythene film manufacturers in the UK?

A: The UK is home to several prominent polythene film manufacturers, including [Insert Polythene Film Manufacturers UK]. These manufacturers offer a wide range of PE film products tailored to diverse industries and applications, backed by quality assurance and customer support.

Q2: Is biodegradable polythene film suitable for food packaging?

A: Yes, biodegradable polythene film can be used for food packaging applications, provided it meets food safety regulations and certification requirements. Manufacturers produce biodegradable films specifically formulated for food contact, ensuring product safety and compliance with industry standards.

Q3: How long does it take for biodegradable PE film to break down?

A: The degradation time of biodegradable PE film varies depending on factors such as environmental conditions, microbial activity, and material composition. In general, biodegradable PE film can break down within several months to a few years, compared to conventional PE film, which may persist in the environment for much longer periods.

Q4: Can recycled PE film be used to produce new packaging materials?

A: Yes, recycled PE film can be processed and used to manufacture new packaging materials, including recycled-content PE film. Recycling facilities collect post-consumer and post-industrial PE film waste, which is then cleaned, melted, and extruded into pellets for subsequent manufacturing processes. Incorporating recycled content into new PE film products helps conserve resources and reduce environmental impact.