MEDICAL DEVICE DEVELOPERS HAVE BEEN COMPELLED TO OUTSOURCE THEIR MANUFACTURING OPERATIONS TO CONTRACT SERVICE PROVIDERS

The in-house development of peptide API requires necessary expertise and capabilities, including design, construction and maintenance of a facility which demands significant capital investments. Therefore, several small drug developers and, at times, certain pharma giants as well, have started outsourcing their manufacturing operations to contract service providers.

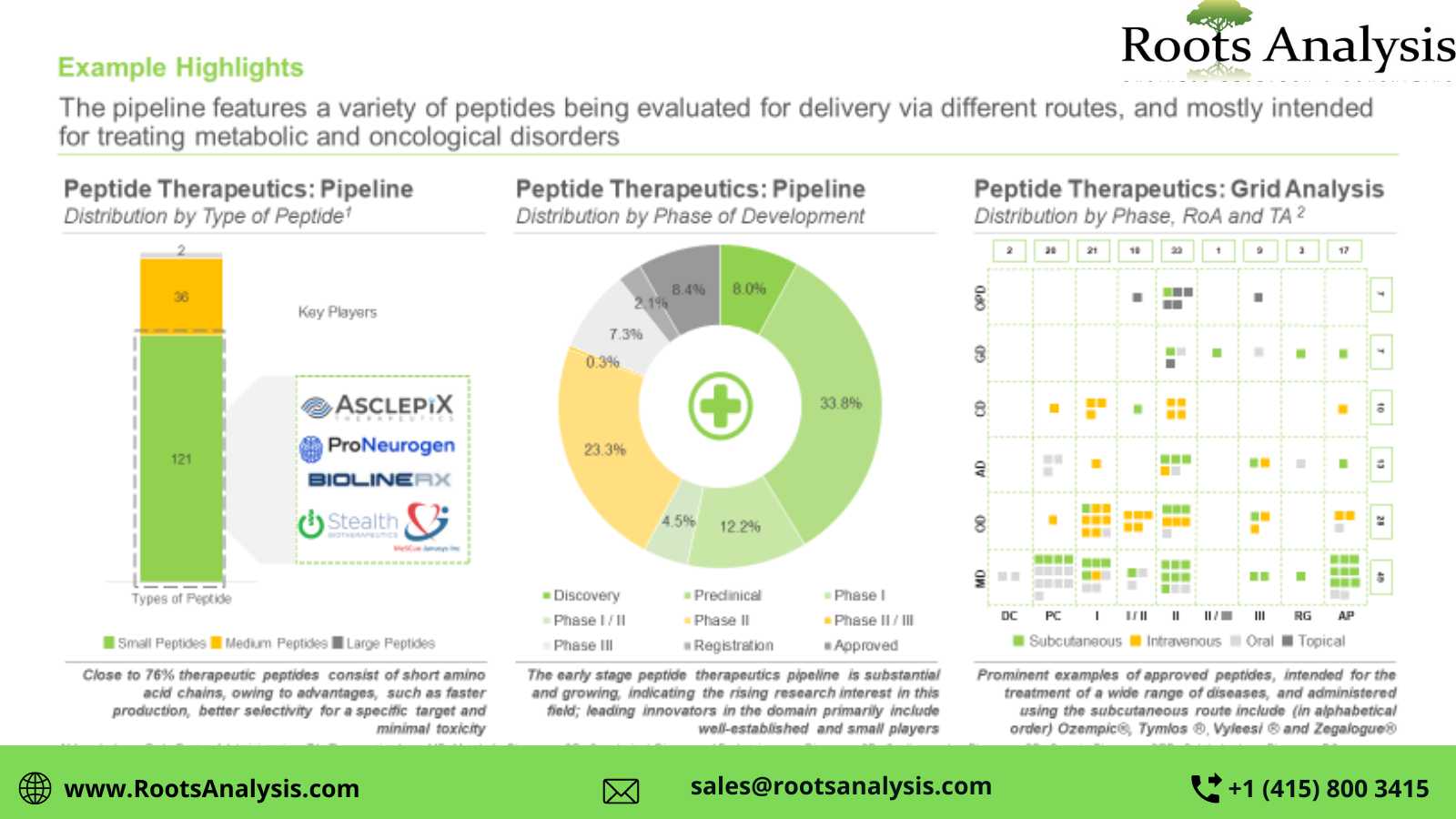

Over the years, the popularity of biologics has led to an evident shift in the focus of pharmaceutical companies, from traditional interventions towards more complex and advanced pharmacological interventions, such as peptide therapeutics. Since the discovery of insulin, the peptide therapeutics market has evolved significantly. The increasing demand for companies capable of offering manufacturing and, in certain cases, development services to biopharmaceutical players has resulted in the establishment of several CMOs. Most of these contract service providers have profound experience in niche and emerging areas. The innate expertise and availability of the required capabilities and infrastructure enables CMOs to effectively fulfil the requirements of their clients, eliminate costly oversights and, thereby, reduce chances of failure. As pharma companies resume full-scale operation after the COVID-19 outbreak, the demand for large-scale peptide therapeutics contract API manufacturing is expected to increase significantly.

To request a sample copy / brochure of this report, please visit

https://www.rootsanalysis.com/....reports/305/request-

In fact, drug developers are actively collaborating with CMOs that offer improved technology platforms to increase the bioavailability of peptide drugs and enhance the efficacy of the production process. The aforementioned factors are likely to drive growth of the contract manufacturing and provide lucrative opportunities to CMOs in the near future. Presently, XX% of the total capacity is available with contract manufacturers catering to the needs for commercial scale operations. Further, majority (XX%) of the peptide API contract manufacturing capacity is installed in facilities based in Europe. However, we believe that, in order to cope up with the increasing demand and maintain a competitive advantage, CMOs should further enhance their existing capabilities and capacities, as well as adopt innovative and efficient production technologies.

For additional details, please visit

https://www.rootsanalysis.com/....reports/view_documen or email sales@rootsanalysis.com

You may also be interested in the following titles:

1. Targeted protein degradation market, 2022-2035

2. Single-Use Upstream Bioprocessing Technology / Equipment Market, 2022-2035

About Roots Analysis

Roots Analysis is a global leader in the pharma / biotech market research. Having worked with over 750 clients worldwide, including Fortune 500 companies, start-ups, academia, venture capitalists and strategic investors for more than a decade, we offer a highly analytical / data-driven perspective to a network of over 450,000 senior industry stakeholders looking for credible market insights.

Contact:

Ben Johnson

+1 (415) 800 3415

+44 (122) 391 1091

Ben.johnson@rootsanalysis.com